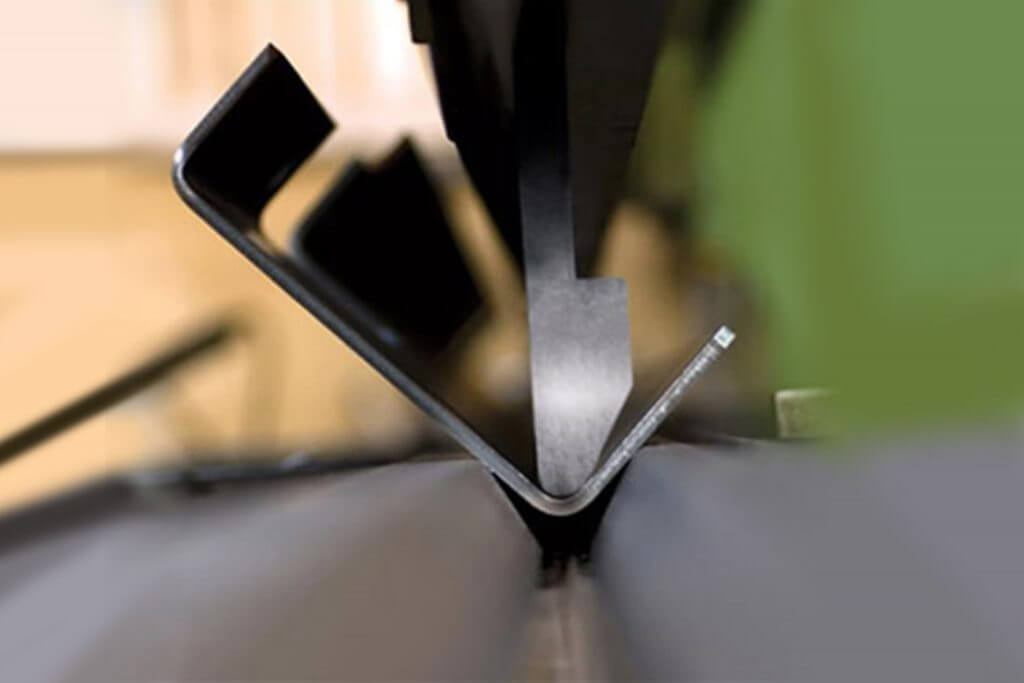

PRESS FORMING

Company has been operating in the field of press forming with a closed area of 2,000 m2 for more than 30 years. It produces hydraulic, pneumatic and eccentric presses up to 150 tons, and products and semi-products for the automotive, construction, defense industry. In addition to these, it makes project partnerships in the sector with welded manufacturing and CNC press brake processes.

KP Pressing can complete the processes within its own structure thanks to its wide machine park and experienced staff and can operate in many sectors with its dynamic staff. For more than 20 years, pedal systems produced in accordance with automotive quality standards for driving courses are available to the whole world. Construction materials used in tunnel formwork and scaffolding systems, fasteners, metal parts of the sampler used in the mining industry are some of the product groups.

It produces hydraulic, pneumatic and eccentric presses up to 150 tons, and products and semi-products for the automotive, construction, defense industry.

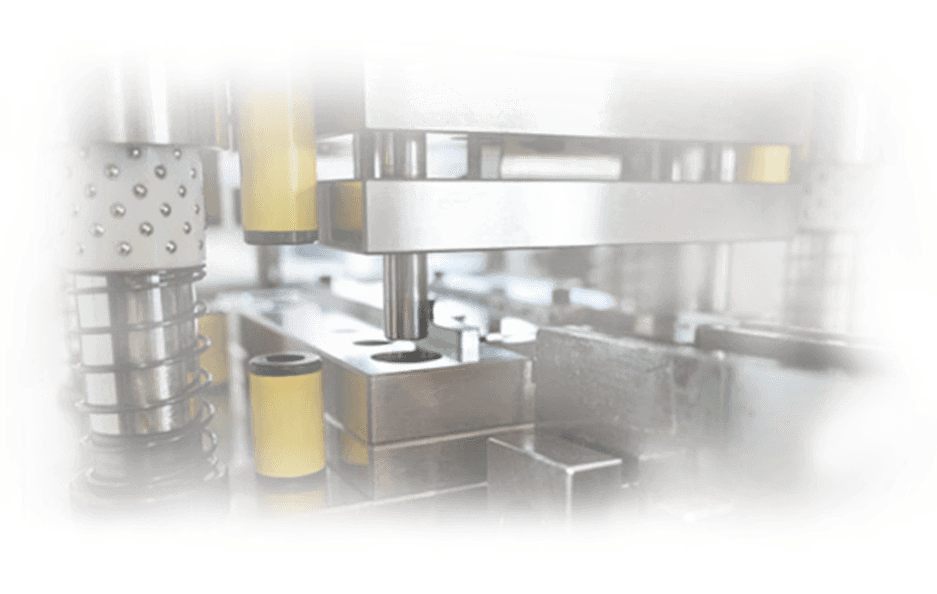

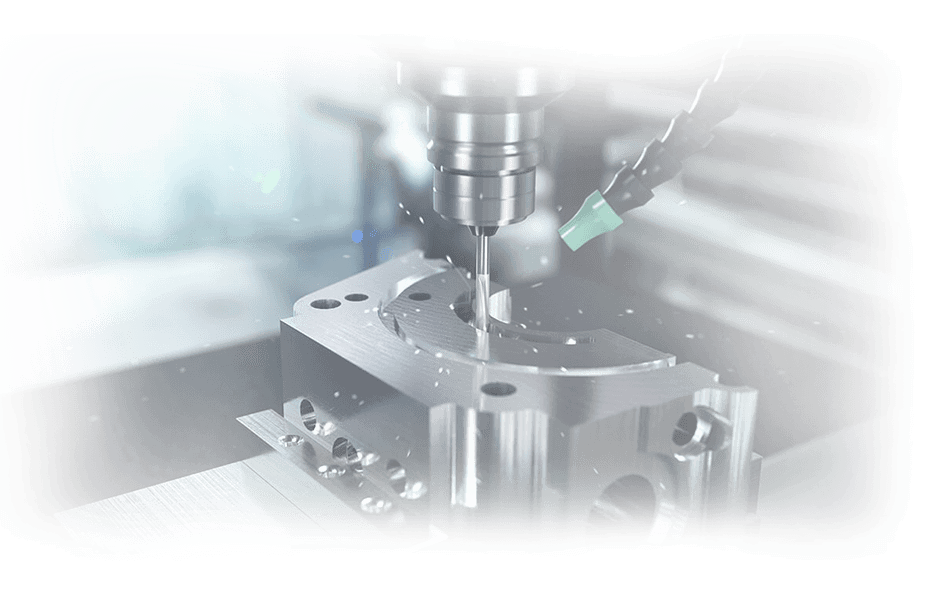

MOLD & DIE

The department, which mainly carries out the mechanical production processes of local defense industry projects, carries out its activities in a closed area of 1500 m². Supporting customers’ R&D studies (material selection, design arrangements, etc.) with their competencies such as machining, wire erosion in aluminum and difficult to process material types (Honeycomb, Invar 36, Inconel 718, Tungsten, PH with stainless steel, titanium, etc.) It allows the creation of suitable products.