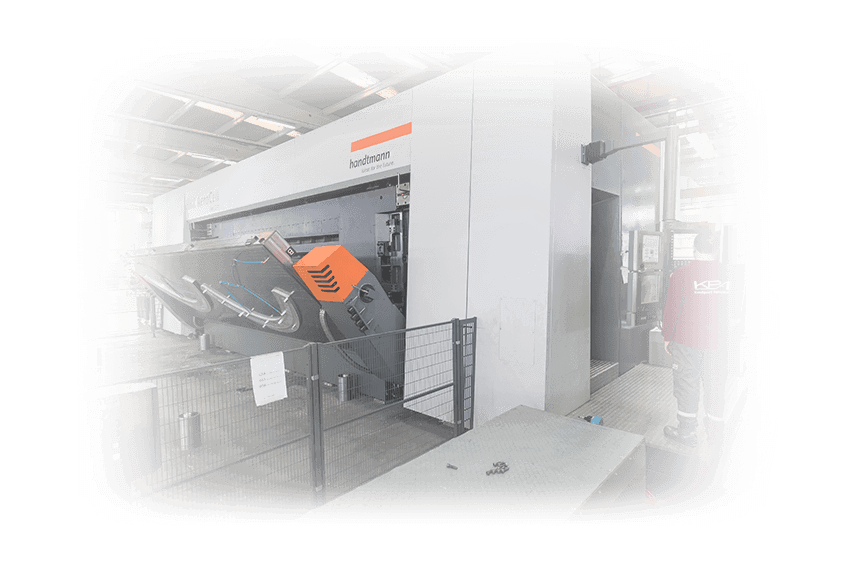

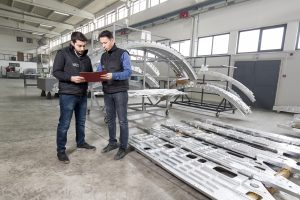

Since its establishment, machining processes have been the driving force of KPA. Company, which has investments in large machining centers suitable for aerospace scales, is known as a structural frame manufacturer in the sector, and is able to meet the machining needs of its customers from 1 millimeter to 15 meters thanks to its modern equipment of all sizes. Aerospace materials such as aluminum, stainless steel and titanium can be processed in more than 70 machining centers.

The parts processing capabilities of KPA, a “Super Precision” machining company, continue to increase in parallel with the technological developments in the world. KPA is shown from the industry giants in terms of engineering, reverse engineering, NC programming, NC manufacturing and NC simulation.

KPA, which offers unlimited solutions to its customers in complex and detailed part processing, stands behind precision of the parts it produces and knows the importance of continuous improvement, so uses the latest technology machine park in precision machining. The machining capability of KPA has always been a reason for preference for its customers.