QUALITY & ENVIRONMENT

KPA Quality Management System; While improving its products, services, systems and processes, it strives to ensure that the entire organization is sustained in an appropriate and effective manner.

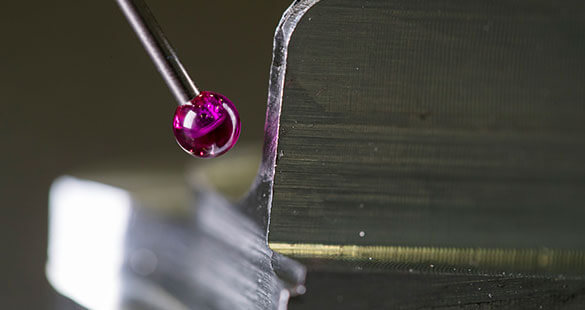

We meet the highest quality requirements required by the industry. AS9100 Rev. D certificate ensures the quality of the aviation production activities we perform. Our special processes, which are a separate area of expertise, are NADCAP accredited, which is the industry norm. All our activities have been carried out for many years to meet the standard quality requirements and we are working to make it better every day.

Everyone from the top manager to the internship in KPA is responsible for the quality of the job. Employees at all levels have responsibility and influence on the concepts of determining the requirements that affect the quality of the outputs of the KPA, meeting these requirements and determining the necessary definitions to carry the quality further.

When it comes to quality management, there are many supporting methods. KPA Quality experts use many methods, measurements, tools and techniques. At the center of all are stakeholders, effective processes, strong leadership and continuous improvement.

KPA shapes its processes in line with customer demands.

You can find our approvals for our processes approved by the largest OEM manufacturers below.

AIRBUS

80-T-35-0014 CLEANING WITH ORGANIC SOLVENTS 80-T-30-6918 FINISHING OF METAL COMPONENTS (DEBURRING,CLEANING) 80-T-30-9910 PREPARATION OF HOLES IN METALLIC MATERIALS FOR FASTENING 80-T-30-4010 MACHINING OF METALLIC COMPONENTS 80-T-39-0132 MARKING WITH INDELIBLE INK ASTM E18 STANDARD TEST METHODS FOR ROCKWELL HARDNESS OF METALLIC MATERIALS ISO 6508 METALLIC MATERIALS – ROCKWELL HARDNESS TEST AITM 1-0070

(incl. ISO 4287)SURFACE ROUGHNESS MEASUREMENTS USING SURFACE STYLUS METHODS AITM6-6004 DETERMINATION OF ELECTRICAL CONDUCTIVITY OF NON-FERROMAGNETIC MATERIALS BOEING

BAC 5619

(Process Code:131)HEAT TREAT OF CORROSION RESISTANT STEEL ASTM E18

(Process Code:806D)STANDARD TEST METHODS FOR ROCKWELL HARDNESS OF METALLIC MATERIALS Quality System (Process Code:003) BOEING APPROVED QMS AS DEFINED IN D1-4426 PROCESSOR REQUIREMENTS SEC 6.16.3 BELL HELICOPTER

4138 CHEMICAL CLEANING OF AIRCRAFT MATERIALS 4012 THERMAL FIT ASSEMBLY 4528 ELECTRICAL BONDING AND GROUNDING OF A/C STRUCTURES 4558 INSTALLATION OF NUT PLATES UTILIZING COLD EXPANSION 4453 INSPECTION, CONDUCTIVITY, OF WROUGHT ALUMINUM ALLOY SHEET, BAR, PLATE, FORGINGS & EXTRUSIONS (HT) 4467 HARDNESS TESTING SQRM MEETS MIN SQRM TUSAŞ

80-T-35-0014 CLEANING WITH ORGANIC SOLVENTS 80-T-30-6918 FINISHING OF METAL COMPONENTS (DEBURRING,CLEANING) BAC 5619 HEAT TREAT OF CORROSION RESISTANT STEELS BAC 5004-1 SOLID RIVET INSTALLATION BAC 5004-2 PERMANENT STRAIGHT SHANK FASTENER INSTALLATION BAC 5117-(2-7-8) ELECTRICAL BONDING BAC 5435 BEARING INSTALLATION AND RETENTION BAC 5300 FORMING, STRAIGHTENING AND FITTING METAL PARTS BAC 5004 INSTALLATION OF PERMANENT FASTENERS BAC 5009 BOLT AND NUT INSTALLATION BAC 5117-3 STANDARD PREINSTALLED GROUND STUD INSTALLATION BAC 5430 FABRICATION AND INSTALLATION OF RESIN BONDED LAMINATED SHIMS AND SOLID FILLERS SS 9201 FASTENER INSTALLATION & ACCEPTANCE CRITERIA SS 7007 GROUNDING AND/OR BONDING ELECTRICAL, PROCEDURE FOR SS 5100 DEBURR AND HOLE SIZES SS 9300 TORQUE, WRENCH & TIGHTENING SS 8630 SEALING AND INSULATION OF MATING SURFACES SS 8640 ADHESIVE BONDING, GENERAL PURPOSE BAC 5300 FORMING, STRAIGHTENING AND FITTING METAL PARTS BAC 5000 SEALING, GENERAL BAC 5010 APPLICATION OF ADHESIVES BAC 5117,

BAC 5117-2,

BAC 5117-7,

BAC 5117-8ELECTRICAL BONDING BAC 5117,

BAC 5117-2,

BAC 5117-3,

BAC 5117-7,

BAC 5117-8ELECTRICAL BONDING BAC 5435 BEARING INSTALLATION AND RETENTION 80-T-30-9910 RILLING,REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES 80-T-30-9910 DRILLING, REAMING AND COUNTERSINKING OF RIVET AND SCREW HOLES 80-T-30-4010 MACHINING OF METALLIC COMPONENTS AIPS/AIPI 03-11-001 MACHINING OF METALLICS 80-T-39-0132 MARKING WITH INDELIBLE INK BAC 5307 PART MARKING SS 8798 IDENTIFICATION MARKING OF PART, METHODS FOR AITM6-6004 DETERMINATION OF ELECTRICAL CONDUCTIVITY OF ALUMINIUM ALLOYS BY EDDY CURRENT METHOD PRI

NADCAP HT STAINLESS STEELS, PRECIPITATION HARDENING